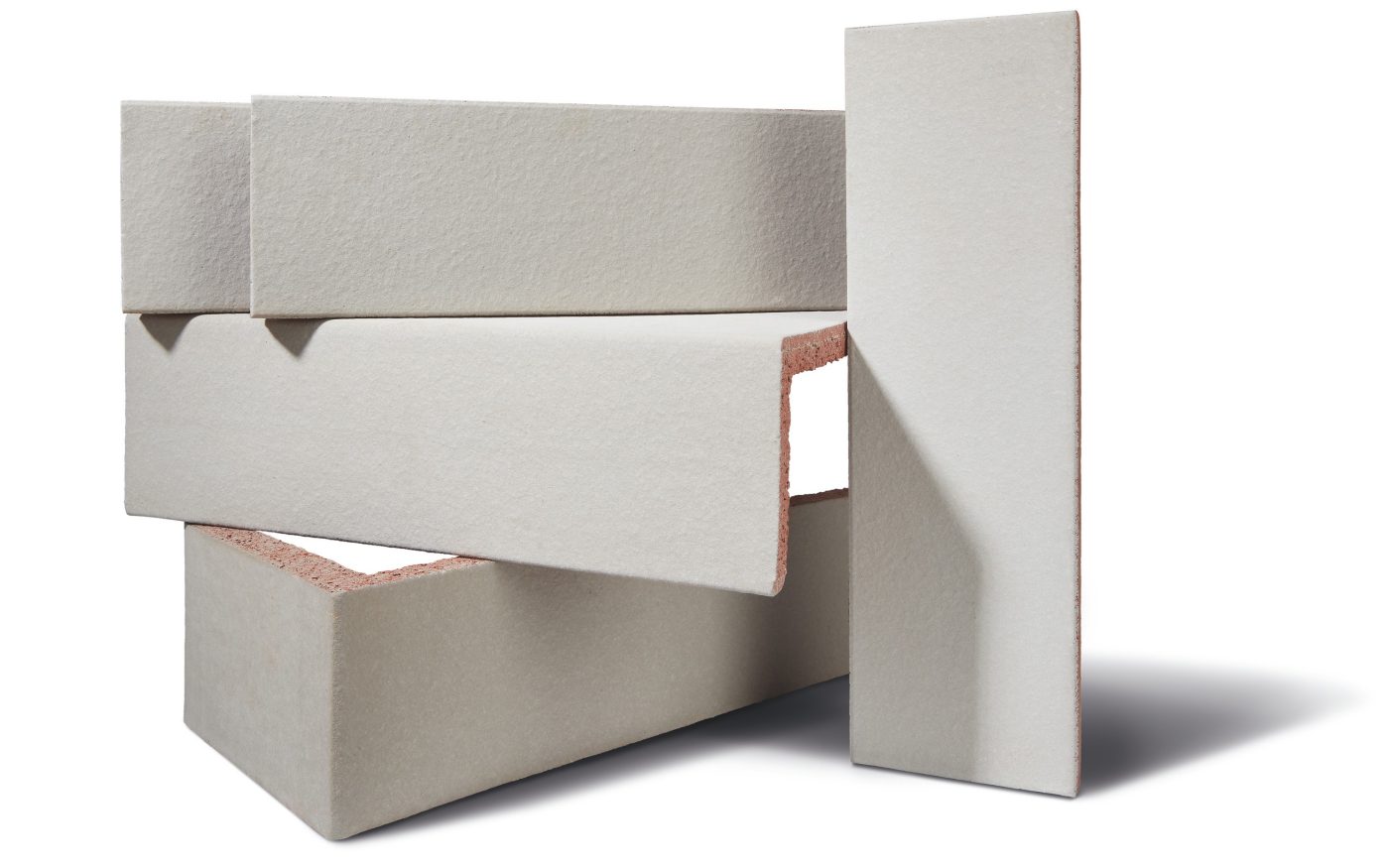

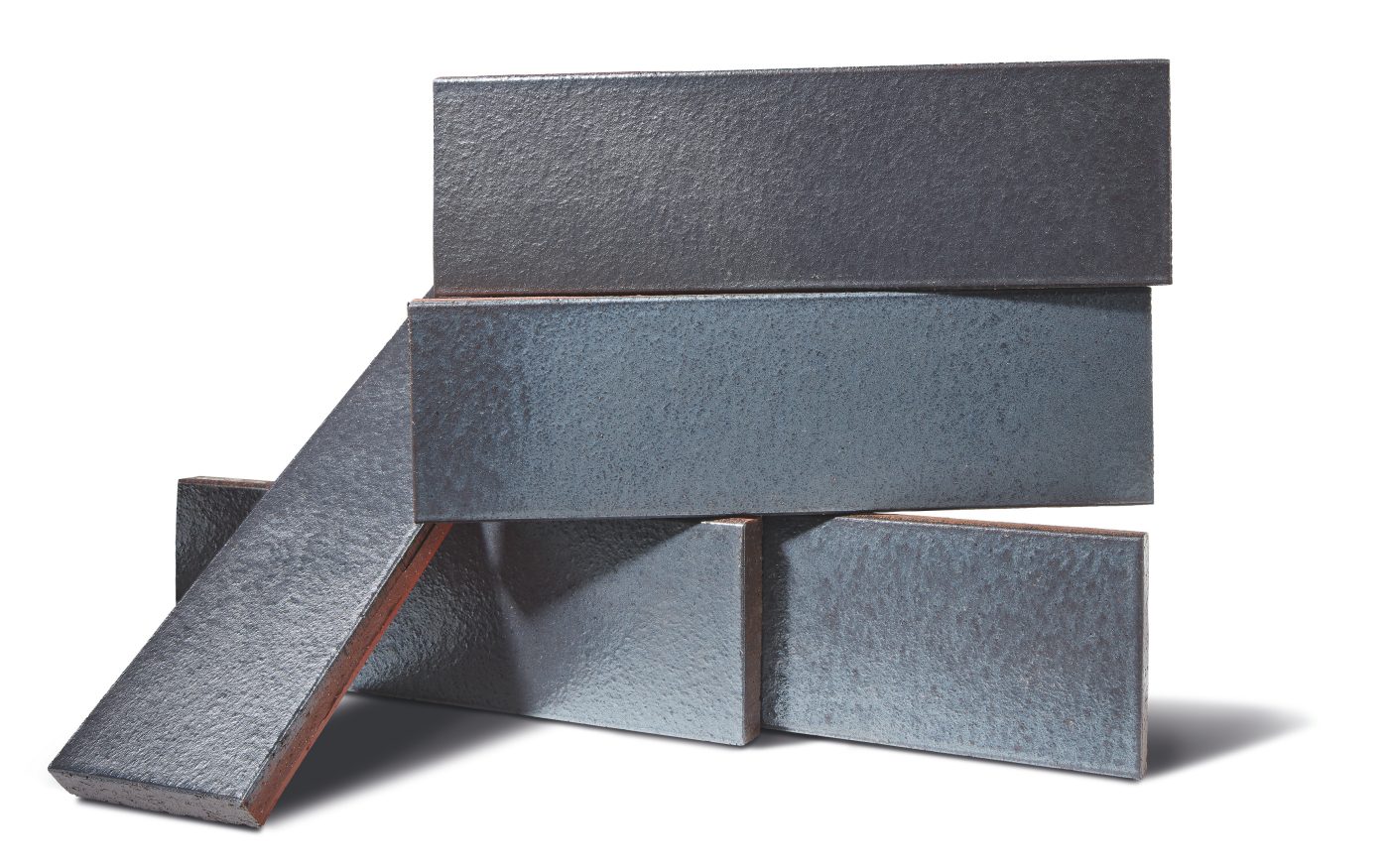

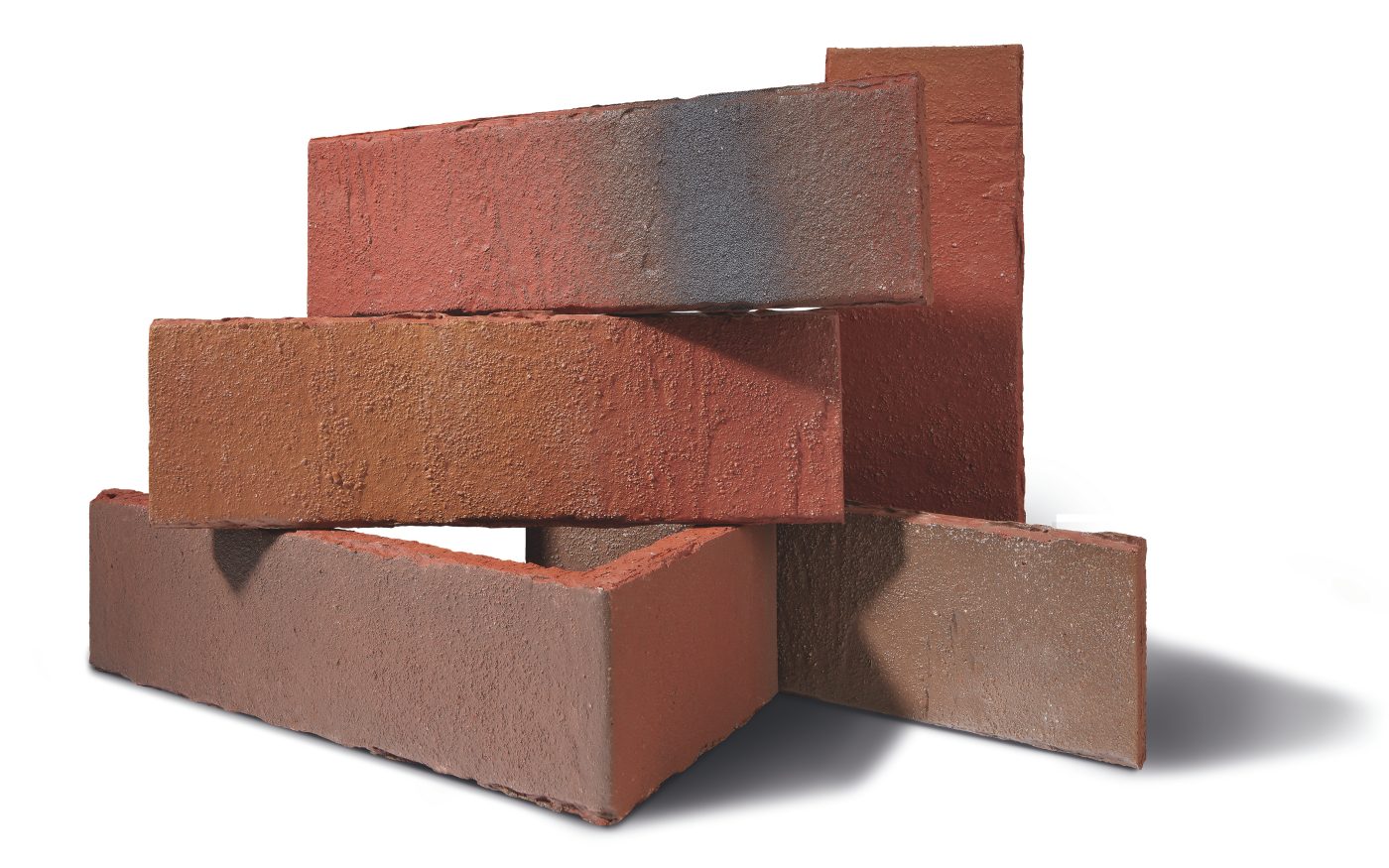

The manufactured extruded brick slip range is a high-quality brick slip with both tight tolerance and low water absorption offering high levels of consistency throughout the build process. Manufactured extruded brick slips conform to EN14411 achieving a very tight size tolerance which is ideal for both off-site and on-site installations where productivity and labour costs are important. The slips offer a reduction in embodied carbon over traditional bricks, and with less water usage during construction provide an overall cleaner build.

Manufactured extruded brick slips are a perfect choice for ETICS and EWI suppliers, pre-cast producers and modular system manufacturers. The slips are purpose-made meaning a significant wastage saving is achieved in comparison to cut brick slips, as well as offering an impressive A1 fire rating. The brick slip range offers excellent environmental and technical credentials alongside effective cost reduction and performance gains. Take a more in-depth look at manufactured extruded brick slips below to discover how you can profit from the numerous impressive benefits the range has to offer.

.jpg)

.jpg)

.jpg)