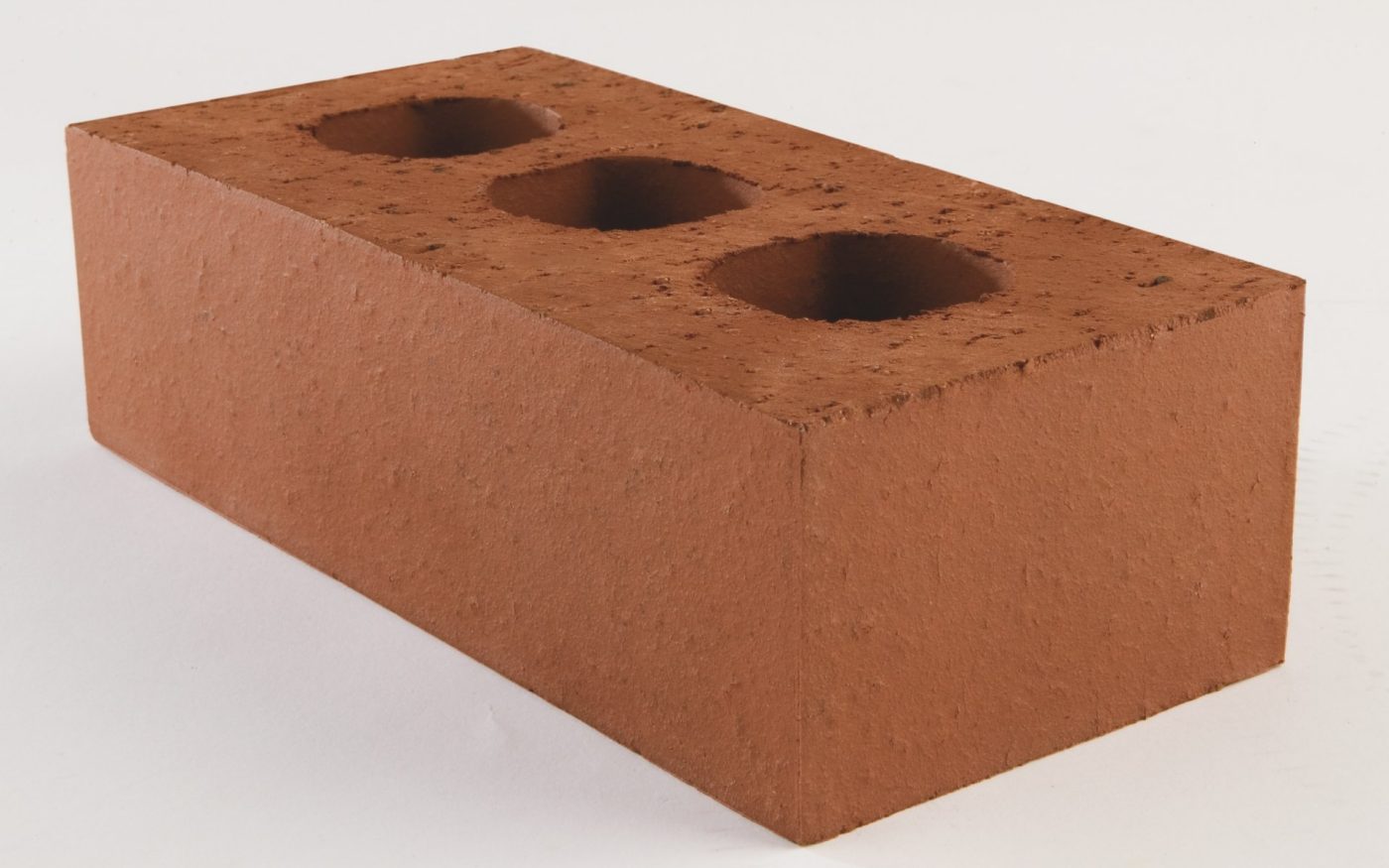

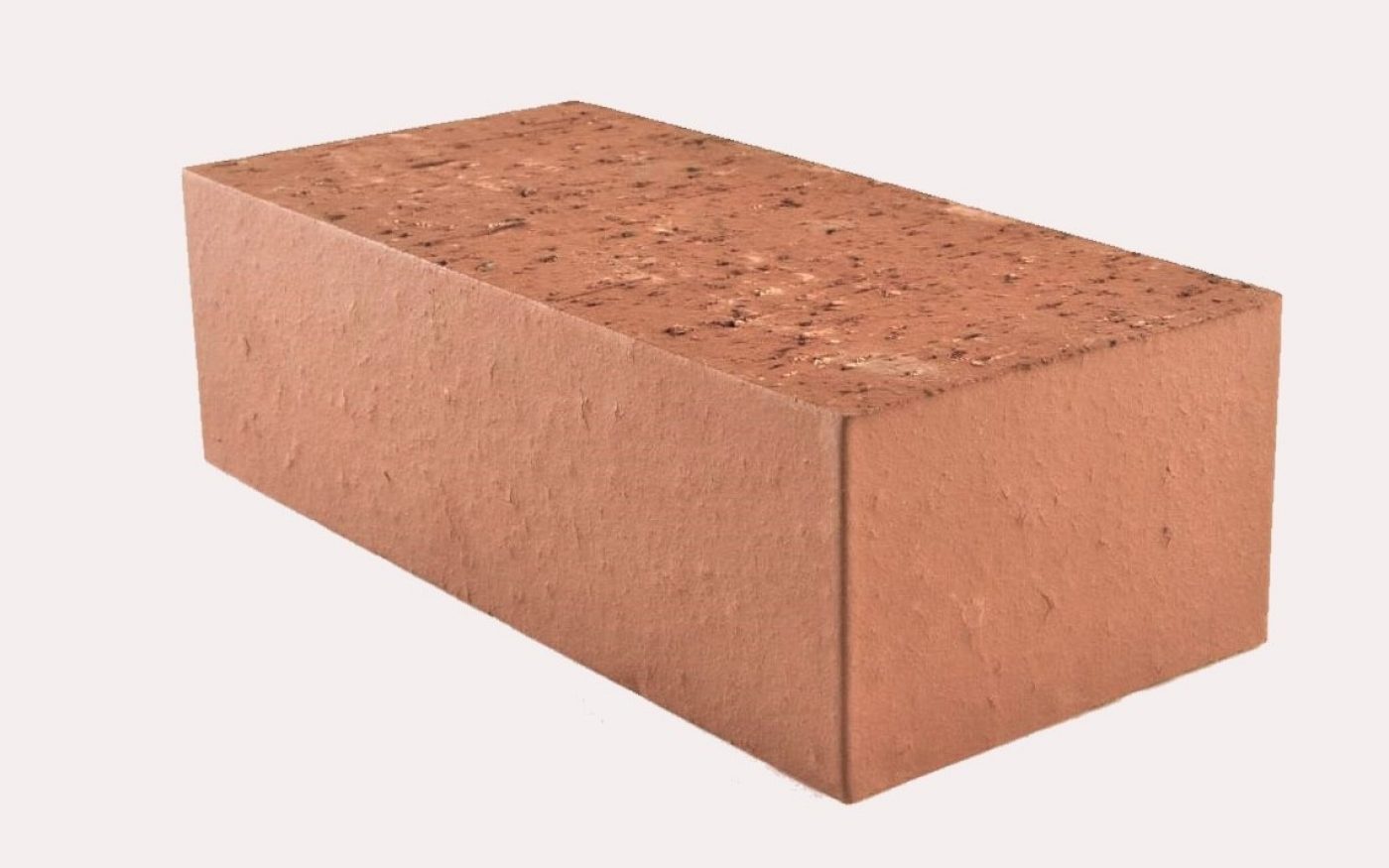

Bricks are produced using a variety of manufacturing techniques which create very different aesthetic effects and performance qualities.

There are three main types of bricks: facing bricks, engineering bricks and common bricks. However, there are many more variations, styles and manufacturing processes that make different bricks suitable for different jobs. When choosing the correct type of brick for your project, it's essential to consider the purpose of the brick, as well as the look and feel you are trying to achieve.

Discover more about the different types of bricks.

.jpg)